To improve nuclear plant safety, the FIND project develops monitoring technologies for both normal and accidental conditions. Some systems are designed to identify defects in metallic pipes at an early stage to prevent failures and anticipate maintenance, while others support accident management by providing additional insights about the progression of the accident. These instruments are essential to help operators detect anomalies early and respond quickly.

But here lies the challenge: some instruments must be able to operate in radioactive environments, whether resulting from normal plant activity or from the accidental release of radioactive products. This requires specific radiation-hardened technologies, and this is precisely where the expertise of the FIND partners comes into play.

"Our goal is to make sure every instrument we test can be trusted, even in the harshest conditions" says Hanaa Houjeij, Research & Development Engineer at ASNR.

Thanks to the IRMA irradiator operated by ASNR, the consortium has access to the right tool to test and demonstrate that the material can withstand radiation. This step is crucial in ensuring reliability and long-term performance once installed in nuclear reactors. That’s why the FIND team will carry out an irradiation campaign in 2026.

What is an Irradiation Campaign?

An irradiation campaign is like a stress test for materials: just as car parts are tested in extreme heat or cold to ensure they don’t fail, instruments and sensors are tested under radiation to check their resistance. Therefore, an irradiation campaign recreates the radiation environment of a nuclear reactor inside a shielded bunker but in a safe and controlled setting for workers. By adjusting how long the instruments are exposed and how strong the radiation is, scientists can simulate :

- the normal conditions inside an operating reactor, and

- the more intense radiation levels that could occur during an accident.

During and after exposure, the team examines how the instruments and sensors behaved under irradiation: do their measurements remain accurate, or have the electronic parts or materials degraded? The high dose rates achieved by IRMA make it possible to accelerate ageing as compared to normal operating conditions, simulating several years of exposure in a few weeks.

FIND’s 2026 IRMA Irradiation Campaign

The FIND gamma irradiation campaign will take place in the IRMA bunker, a facility designed to study the effects ofgamma radiation on materials and equipment. IRMA uses Cobalt-60, a radioactive form of cobalt that continuously emits high-energy gamma rays, similar to X-rays, to simulate the gamma radiation conditions inside a nuclear reactor. The facility is used for both internal ASNR research projects and external services.

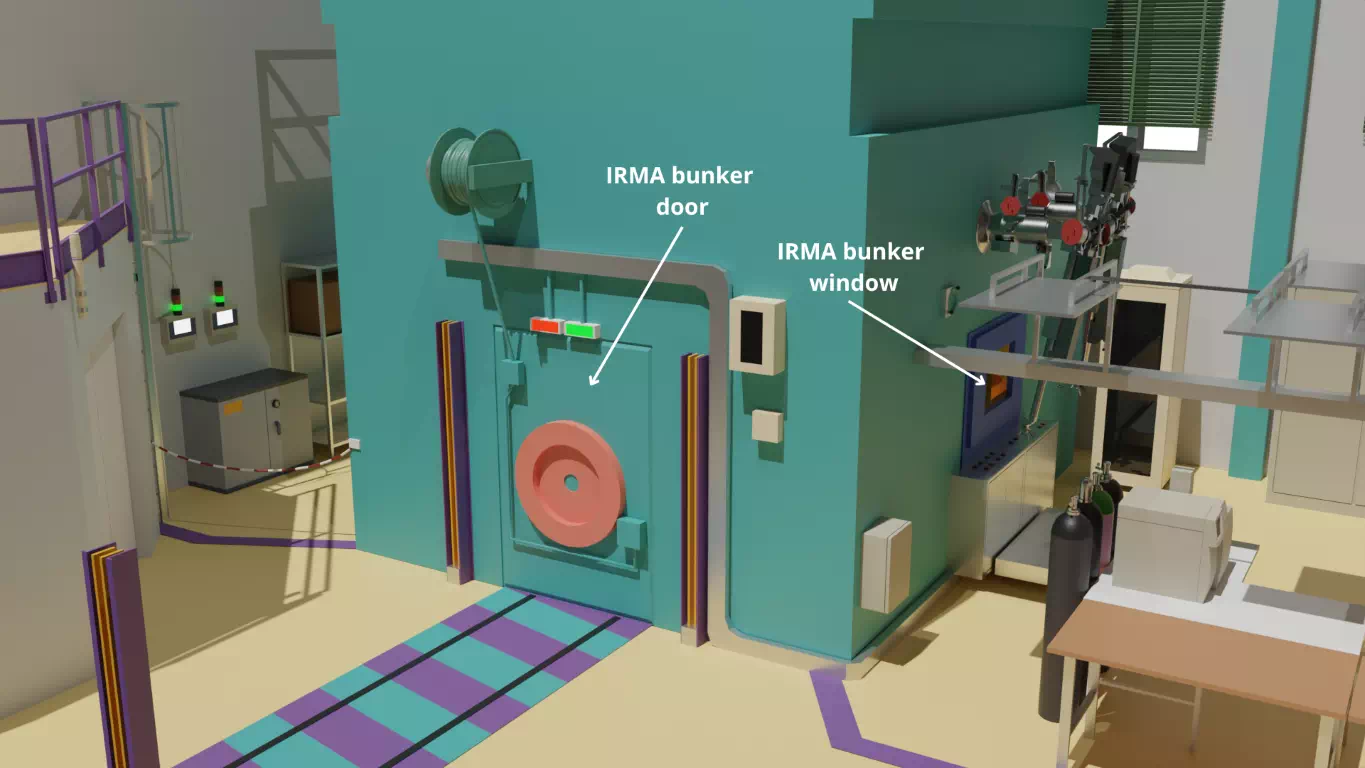

Representation of IRMA’s facility. The irradiation bunker is represented in green. Outside irradiation periods, the bunker can be accessed through the door. The setup can be monitored visually during irradiation through the window.

Conducting irradiation tests at IRMA involves three main steps:

- Preparation & feasibility study: Once the dose and dose rate requirements are defined, along with the dimensions of the material to be tested, IRMA's operational team first performs a feasibility study, which includes planning and the design of the experimental setup. Using RayXpert© simulation software, the team determines the exposure configuration, such as the optimal distance between the Cobalt-60 radiation sources and the material to be irradiated.

- Experimental verification: A test model representing the material is used and radiation intensity are measured at each reference point by using an ionization chamber, which measures radiation intensity (dose rate) by detecting ions produced in a volume of gas. This step allows the team to measure dose rates and make configuration adjustments if needed.

- Irradiation: On the installation day, the actual material is installed in its designated position, and the gamma irradiation is initiated.

"This testing is essential. It gives us confidence that when these instruments are installed in a reactor, they’ll deliver accurate data under irradiation" explains Hanaa Houjeij, Research & Development Engineer at ASNR.

Key Advantages of the IRMA Facility :

- A safe, non-contaminated environment: IRMA facility uses independent, remotely operated cylindrical Cobalt-60 sealed sources to reproduce gamma radiation conditions found inside a nuclear reactor in normal operating or accidental conditions, while keeping the environment safe and free from contamination risk for researchers or technicians, who can enter the bunker between tests.

- A flexible environment: The facility offers a large internal volume (24 m³) and experimental area (15 m²) for varied test configurations, can simulate a wide range of radiation levels, from mild (1Gy/h) to extreme (25 kGy/h with fresh sources) and supports test durations ranging from a few minutes to several weeks. It can reach doses up to a few MGy, representative of nuclear severe accidents.

- Real-time monitoring: Scientists can observe how instruments and materials behave during irradiation.

- The support of simulation and planning tools: The RayXpert© simulation software associated with in-situ measurement allows for the optimal positioning of the Cobalt-60 source and the material to be irradiated as well as dose rate mapping.

The 2026 FIND irradiation campaign at IRMA will help ensure that the instrumentation developed in the project istough, trustworthy, and ready to perform even in the harshest environments, a key step toward their industrial deployment. The piezoelectric sensors, Fibre Bragg Grating sensors, humidity sensors (traditional and based on heated thermocouples) and extensometry gauges developed by Framatome GmbH, CEA LIST, VÚEZ a.s. and IPP Center LLC will be tested under doses and dose rates representative of both normal reactor operation and severe nuclear accident conditions. A second campaign is planned in the project to test other sensors and push the systems of the 1st campaign to their limits.